Sustainable polyurethane composite materials: Innovative solar photovoltaic module frame materials, achieving new breakthroughs in the photovoltaic industry.

Polyurethane composite Solar Panel Frames demonstrate outstanding material performance. As a non-metallic material, polyurethane composite materials are made of a high-density polyurethane resin matrix and a double-layer polyester fiber reinforcement layer composite structure. Compared with traditional aluminum metal frames, these frames can reduce the overall costs of solar panel manufacturers and improve energy efficiency.

Achieved through continuous pultrusion technology, this material features zero-porosity high-density molding, with a density 30% lower than aluminum alloy, and exceptional mechanical properties. Its axial tensile strength exceeds that of ordinary aluminum alloy by more than seven times. It also exhibits robust resistance to salt spray corrosion and chemical corrosion. Its core weathering performance meets the most stringent C5M marine corrosion protection grade under ISO 12944 standards, enabling it to withstand salt spray, intense UV radiation, temperatures up to 85°C, humidity levels of 95%, and chemical corrosion over the long term. It is designed for a service life exceeding 25 years, with performance degradation rates below 1% after accelerated aging testing (PCT 48h/salt spray/UV).

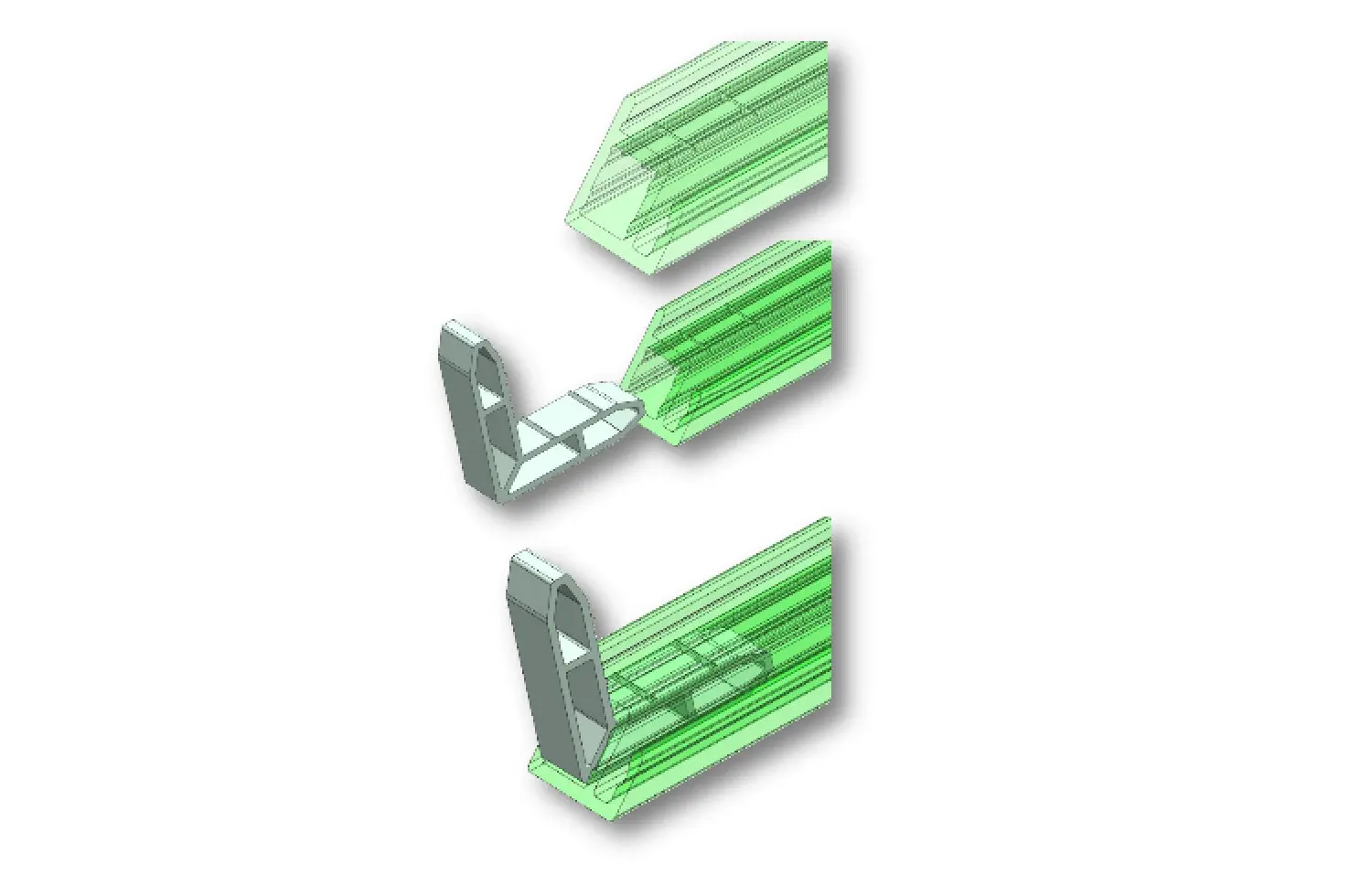

This product breaks through the limitations of traditional metal frames: shear strength is increased by 40%, and fatigue recovery is significantly better than aluminum alloy; the integrated load-bearing surface design avoids the risk of cracking during installation; insulation properties eliminate the need for grounding, completely eliminating the risk of potential-induced degradation (PID); the thermal expansion coefficient is precisely matched to photovoltaic glass, maintaining zero deformation under extreme temperature differences from -40°C to 85°C. Two standardized profiles are available: 30×20mm (compatible with 2278/2382/2465×1134 modules) and 33×20mm (compatible with 2384×1303 modules). These profiles are equipped with the sixth-generation multi-tooth interlocking corner code patent technology, enabling a gap of less than 0.5mm for a hole-free installation structure, with a 35% increase in shear strength, and a 50% increase in installation efficiency.

Supports block-type (distributed rooftop/agricultural PV), bolt-type (large-scale ground-mounted power plants/offshore wind resistance >5400 Pa), and composite installation (floating water surface power plants), certified by TÜV (No. B 124976 0001 Rev.00). Field-tested verification: 6 hours of continuous testing under a 5,400 Pa forward + 2,400 Pa reverse cyclic load with zero failures; power generation degradation rate of only 0.23% at 25°C constant temperature (national standard limit: 0.5%); carbon footprint over the entire lifecycle is one-third that of aluminum alloy frames, enabling photovoltaic systems to achieve high reliability, low cost, and zero carbon emissions through synergistic optimization.